Previous Molds making and Free products design

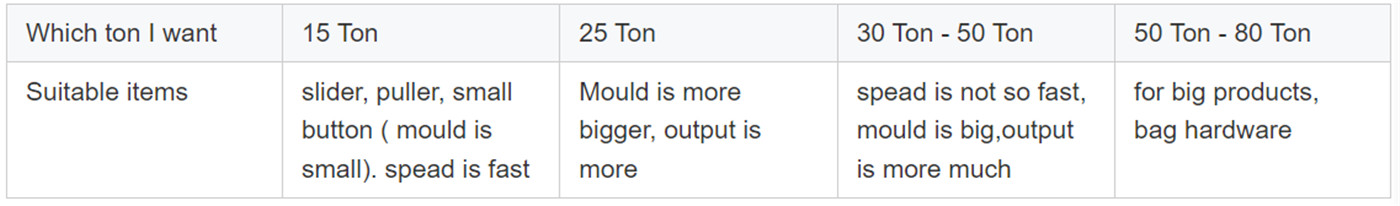

Our Plastic Injection Molding Services

Utilizing CNC Machining to Deliver Superior Results

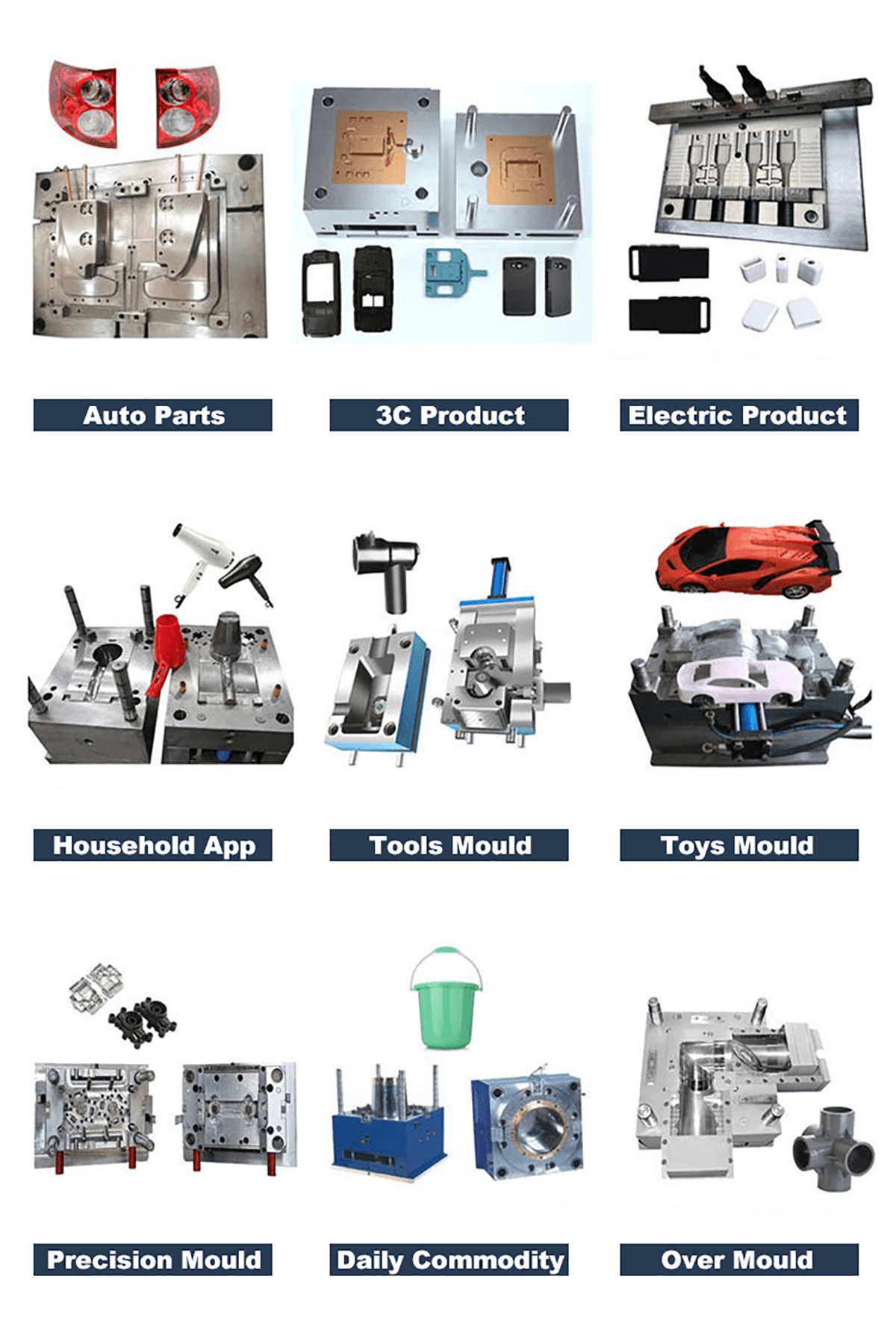

In the field of manufacturing, the manufacturing process of plastic injection molds plays a vital role. These molds are crucial to the production of various products, including household appliances, toys, 3C electronic equipment, auto parts and daily necessities, etc. In our company, we take great pride in providing first-class plastic injection molding services. With our previous experience and expertise, we have mastered the art of manufacturing molds to the highest industry standards. In addition, we employ CNC machining, an innovative manufacturing process that guarantees fast and precise production of injection molded parts.

About us:

Our company has an impressive track record in the field of mold production. With years of industry experience, we have successfully handled various types of molds to meet the needs of different industries. From housewares to cutting-edge electronics, we develop a vast range of products to ensure customer satisfaction every time. Our commitment to excellence and attention to detail has established our reputation as a trusted plastic injection mold supplier.

Learn about injection molds:

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into custom molds. This process can create complex shapes and structures that would otherwise be difficult to achieve. The plastic material solidifies inside the mold, taking on the shape and design of the mold cavity. Once cooled and hardened, the molded parts are ejected, ready for further processing or assembly.

Injection mold CNC machining:

In our company, we have made CNC machining an integral part of our manufacturing process. CNC (Computer Numerical Control) machining is a technique that uses a computer control system to operate precision machinery. In the field of plastic injection molds, CNC machining improves efficiency and precision, resulting in high-quality products.

There are many advantages to using CNC machining in plastic injection mold production. First, it significantly reduces the production time required for each mold. Computer-controlled systems enable fast, precise machining for faster project completion. Reduced lead times are a major benefit for businesses as it directly translates into shortened production cycles and faster time-to-market.

Second, CNC machining ensures exceptional precision in the production of plastic injection molds. Automated control systems are capable of creating highly complex designs with the utmost precision. This level of precision ensures that the final product faithfully replicates the intended mold, meeting the exact specifications and requirements of the customer.

Additionally, CNC machining enables repeatability in the production of plastic injection molds. A computer control system ensures that each mold produced is an exact replica of the original design. This consistency is critical, especially when manufacturing products at scale or maintaining consistency between different product iterations.

in conclusion:

our company takes great pride in providing a comprehensive service for injection molds. We have a proven track record of supplying top-notch molds for various fields such as home appliances, toys, 3C electronic equipment, auto parts and daily necessities. Our utilization of CNC machining further enhances our ability to produce molds quickly and accurately. This unique manufacturing process ensures that our customers quickly receive perfect replicas of the plastic parts they need. Whether you need simple molds or highly complex designs, we can provide fast and satisfying solutions to your plastic injection molding needs.

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

| Shaping Mode | Fans Plastic Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm