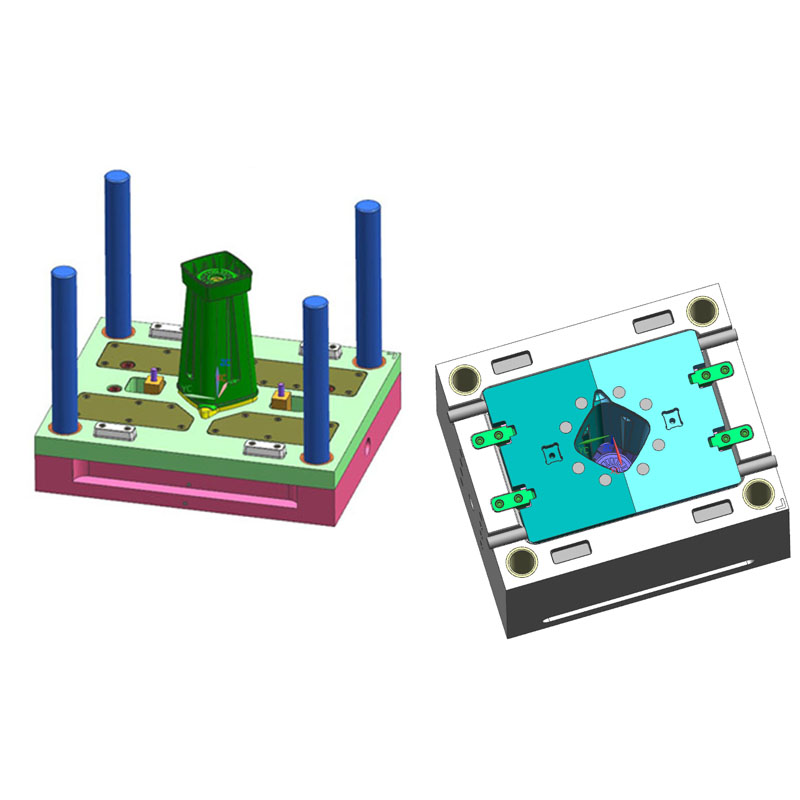

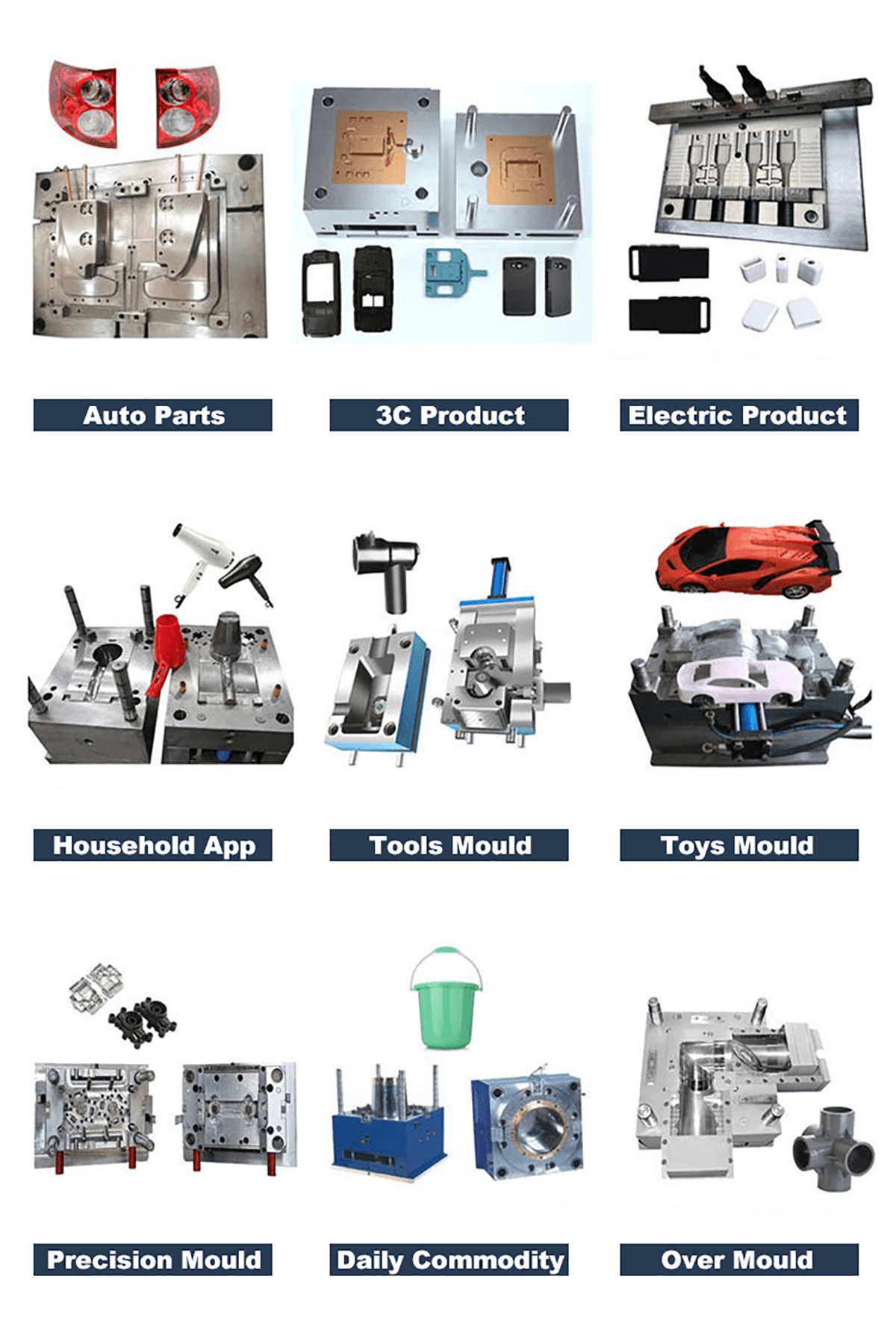

Previous Molds making and Free products design

Plastic Injection Molding for Home Appliances

Home appliances are an integral part of every home. Consumers rely on them for cooking, personal grooming,entertainment, and many other essential applications. At Hongshuo Mold, we specialize in providing injection molding solutions for businesses that manufacture these important products. We are dedicated to offering designs and plastic home appliance products that are manufacturable and deliver a delightful consumer experience.

Home appliance injection molds offer a valuable solution for reducing household waste by manufacturing parts for various appliances like washing machines, refrigerators, and other home appliances. These molds are crafted from durable materials such as stainless steel and can be customized to perfectly fit the specific requirements of each appliance.

As a trusted supplier to renowned manufacturers of home appliances and office supplies, Hongshuo Mold provides comprehensive resources to enable our clients to focus on key priorities in the home appliance market: zero defects and lower overall costs. Our expertise extends to the construction of various household product parts, including those designed for home use, such as injection parts for washing machines and kitchen products. Additionally, we have the capabilities to build office equipment like printers and computers, as well as food containers with thin walls.

Plastic Injection Molding:

A Revolutionary Process That Creates A Variety Of Useful Plastic Products

In manufacturing, plastic injection molding has become a revolutionary process that has forever changed the way plastic products are made. It paves the way for high-volume, cost-effective production with outstanding repeatability and precision. This article aims to explore the world of plastic injection molding and shed light on the various plastic products manufactured using this method.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that injects molten plastic material into a mold cavity under high pressure. A plastic material is usually thermoplastic, meaning it can be melted and solidified multiple times without significantly reducing its physical properties. The process begins with the heating and melting of the plastic material, which is then injected into the mold cavity using a screw injection system. Once the material has cooled and solidified inside the mold, it is ejected and a new cycle begins.

The Versatility of Plastic Injection Molding

One of the main advantages of plastic injection molding is its unrivaled versatility. The process can produce plastic products of varying complexity and size. From small, complex components to large automotive components, plastic injection molding can handle it all. Let's delve into some of the different plastic products that are commonly made using this manufacturing method.

1. Packaging materials:

Injection molding plays a vital role in the production of a wide variety of packaging materials widely used in the food, beverage and consumer goods industries. Plastic bottles, lids, containers and tubs are just a few examples. The process produces lightweight yet durable packaging that ensures product safety, convenience and extended shelf life.

2. Consumer Electronics:

Plastic injection molding is widely used in the production of consumer electronics. From mobile phones and laptops to televisions and game consoles, a large percentage of these devices are manufactured using injection molding. This manufacturing technique enables complex designs, tight tolerances, and smooth finishes that are critical to the aesthetics and functionality of electronic products.

3. Auto parts:

The automotive industry relies heavily on plastic injection molding to produce various vehicle components. Interior components such as dashboards, consoles, door panels and seating components are often manufactured using this process. In addition, exterior components such as bumpers, grilles and mirror housings are injection-molded. The ability to produce complex shapes, integrate multiple functions and achieve lightweight designs makes injection molding ideal for the automotive industry.

4. Medical devices:

Injection molding plays a vital role in the production of medical devices and equipment. Components such as syringes, stopcocks, catheters and drug delivery systems require high precision, biocompatibility and sterilability. Plastic injection molding enables the mass production of these complex and delicate medical components while ensuring strict quality control measures.

5. Toys and leisure products:

Injection molding revolutionized the toy industry, allowing mass production of a wide variety of toys and entertainment products. Plastic injection molds make it easy to create delicate and colorful toys. Additionally, items such as sports equipment, gardening tools, and camping gear benefit from the efficiency and speed that injection molding offers.

6. Household items:

Many of the plastic household items we use every day are manufactured by injection molding. Items such as kitchen utensils, storage containers, clothes hangers and small appliances are made through this process. Injection molding can produce these products quickly and cost-effectively, making them accessible to the mass market.

in conclusion:

Plastic injection molding has undoubtedly revolutionized the production of plastic products across industries. With its versatility, efficiency, and ability to manufacture complex parts with the highest precision, this manufacturing process has become the first choice of countless manufacturers around the world. From packaging materials to automotive parts, electronics to medical devices, toys to household items – plastic injection molding has reshaped our world, creating a variety of useful plastic products that improve our everyday lives.

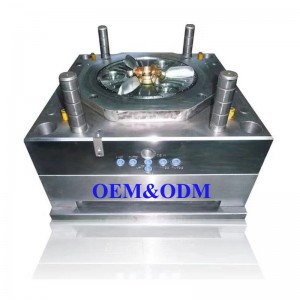

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

| Shaping Mode | Fans Plastic Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm