Previous Molds making and Free products design

Benefits of Home Appliance Injection Molding

The process of home appliance injection molding utilizes plastic injection molds to create products designed specifically for home appliances. This process offers cost-effectiveness, allowing manufacturers to produce products with diverse features and designs. Moreover, it is a sustainable approach that reduces waste and energy consumption. Its applications span across different industries, including automotive, medical, and of course, home appliances. The process excels in producing complex parts with exceptional accuracy and repeatability.

Home appliance injection molding brings numerous benefits to manufacturers and consumers alike. From enhanced design accuracy to reduced production costs, this molding technique contributes to making home appliances more efficient, visually appealing, and affordable. Moreover, this process is often more environmentally sustainable compared to traditional production methods, making it an ideal choice for those seeking to minimize their ecological footprint.

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

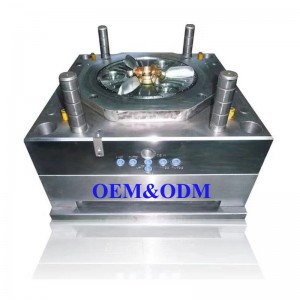

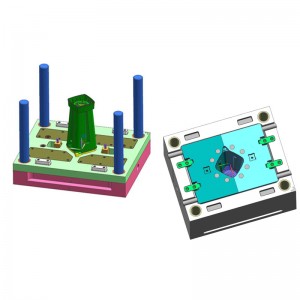

| Shaping Mode | Fans Plastic Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

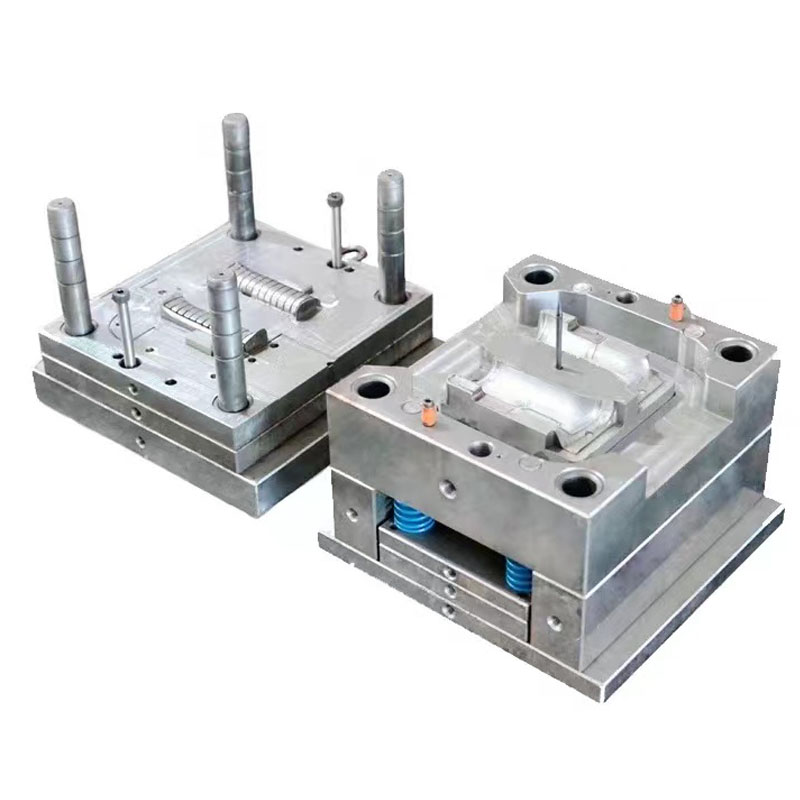

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

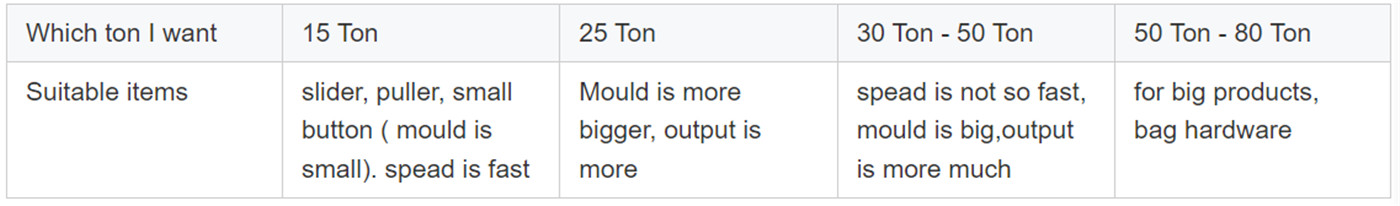

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

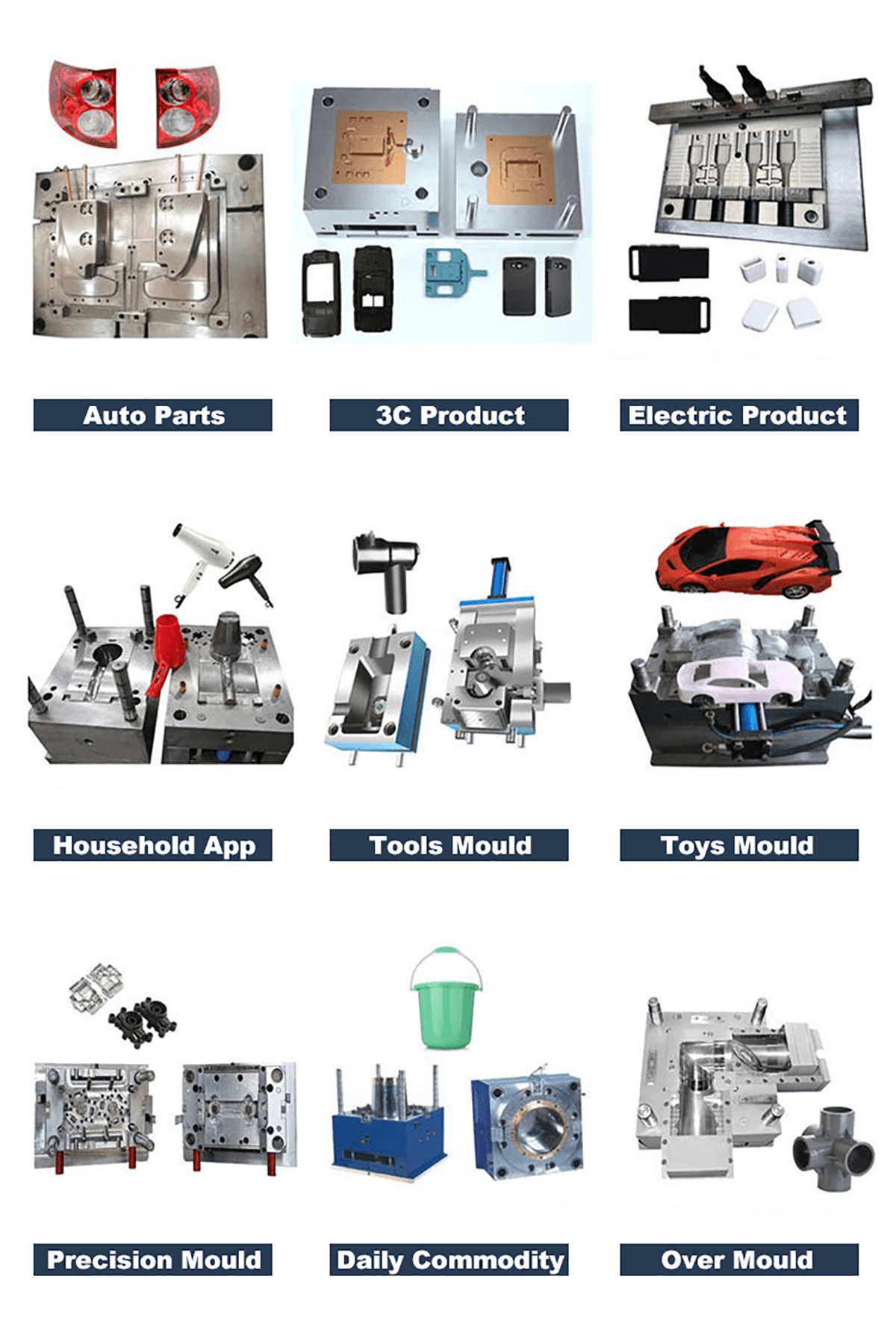

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm