“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for Hot Selling for Injection Mould Maker for Helical Gear Units, The main target of our corporation would be to live a satisfactory memory to all of the prospects, and create an extended term business enterprise romantic relationship with purchasers and users everywhere in the planet.

“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for China Plastic Spur Gear and Gear Box, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, in depth meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

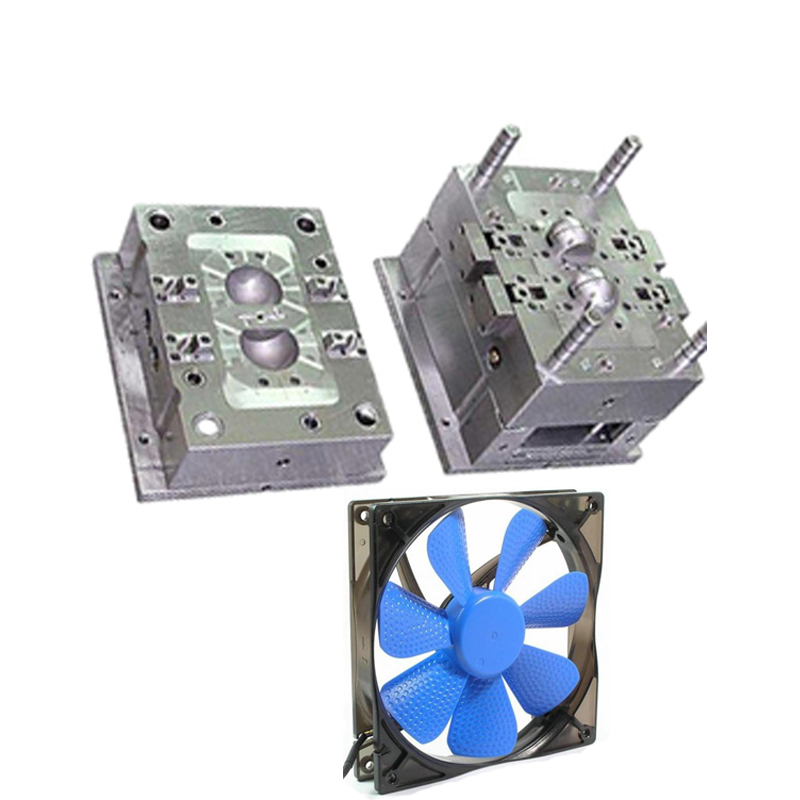

Previous Molds making and Free products design

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

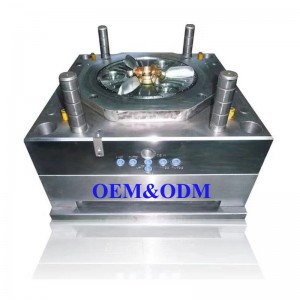

| Shaping Mode | Fans Plastic Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

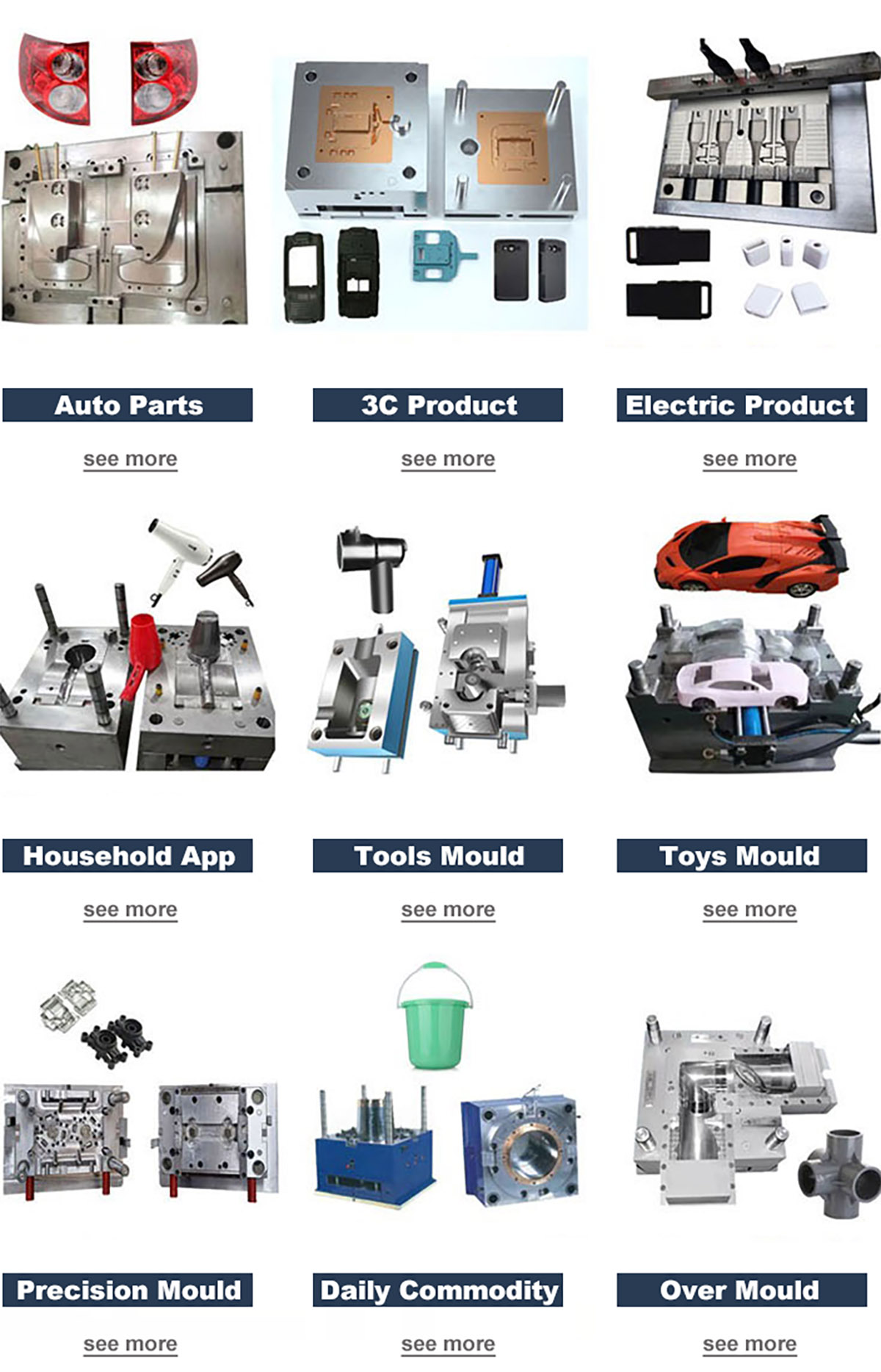

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

1. Do you sell spare parts for die casting mould?

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

2. What is your mold insert made of?

HSLD: Our mold insert is made of DAC.

3. What is your moving core made of?

HSLD: Our moving core is made of FDAC.

4. What is the tolerance of your moving cores?

HSLD: The grinding dimension tolerance of each mold core is 0.02mm and the engraving dimension tolerance is 0.02mm, so that we can ensure that the product size does not have any serious size deviation.

5. Can only samples be produced?

HSLD: Yes.

6. What is the accuracy of the products processed by the drawings?

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm”Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for Hot Selling for Injection Mould Maker for Helical Gear Units, The main target of our corporation would be to live a satisfactory memory to all of the prospects, and create an extended term business enterprise romantic relationship with purchasers and users everywhere in the planet.

Hot Selling for China Plastic Spur Gear and Gear Box, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, in depth meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

-

Factory Directly supply Manufacture Cheap Plast...

-

OEM Customized Plastic Mold Injection Mould Pla...

-

OEM/ODM Factory Customized Clear/Diamond Rectan...

-

Big Discount High-Quality 0.5-60 Ml Barrel Gask...

-

China OEM Plastic Hot Runner Injection Mold Maker

-

Factory Directly supply Customized Plastic Wate...