“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for Factory Selling Quick Prototype Custom Plastic Injection Moulding Parts Polyurethane Molding Mould Mold Tooling Accessories Maker in China with ISO Certification, We’ve been glad that we have been steadily escalating using the energetic and long lasting assist of our pleased shoppers!

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for China Plastic Mold and Plastic Molding Service, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of “Standing in Domestic Markets, Walking into International Markets”. We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

Previous Molds making and Free products design

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

| Shaping Mode | Plastic Parts Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Appliactaion

Assembly

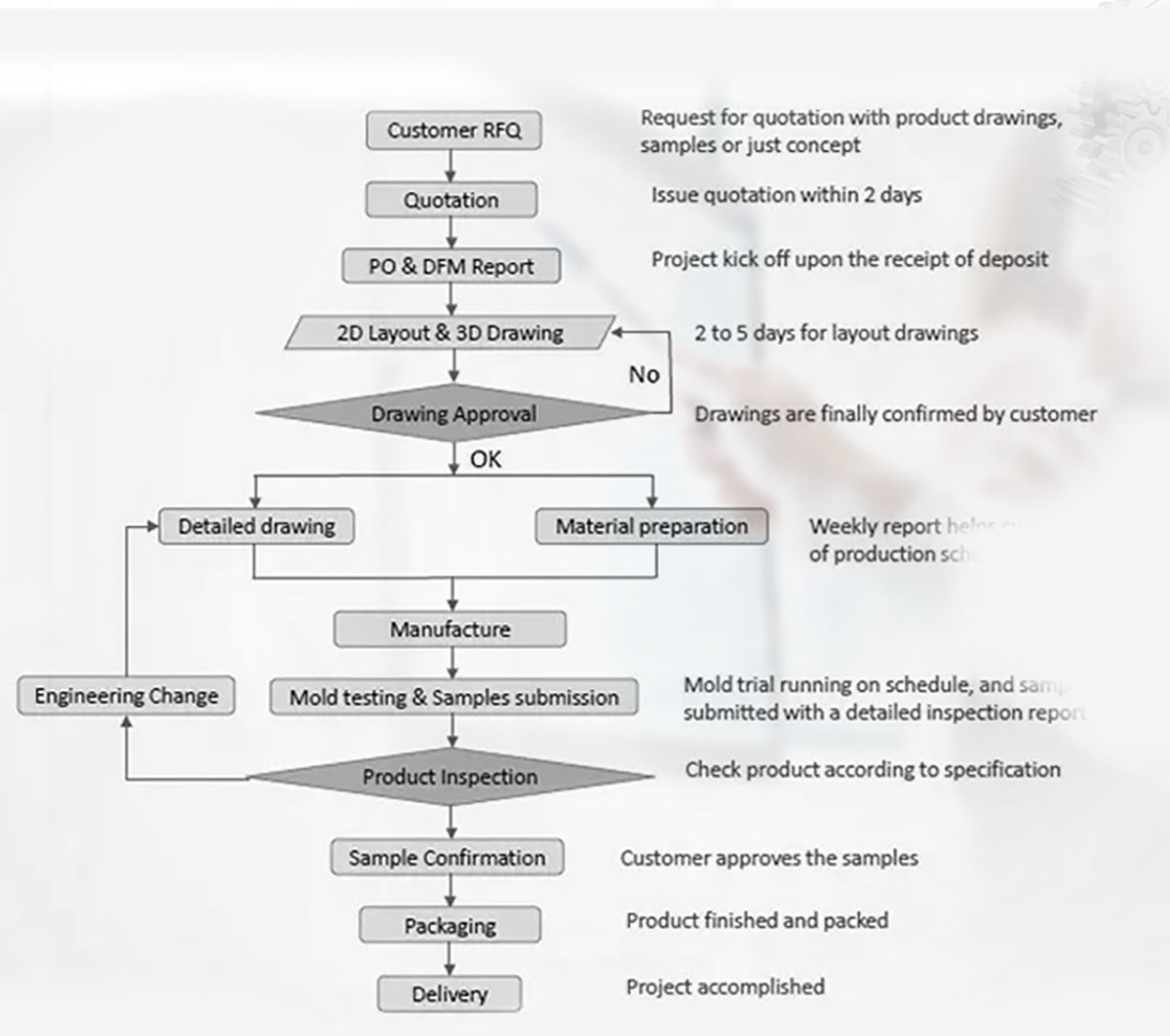

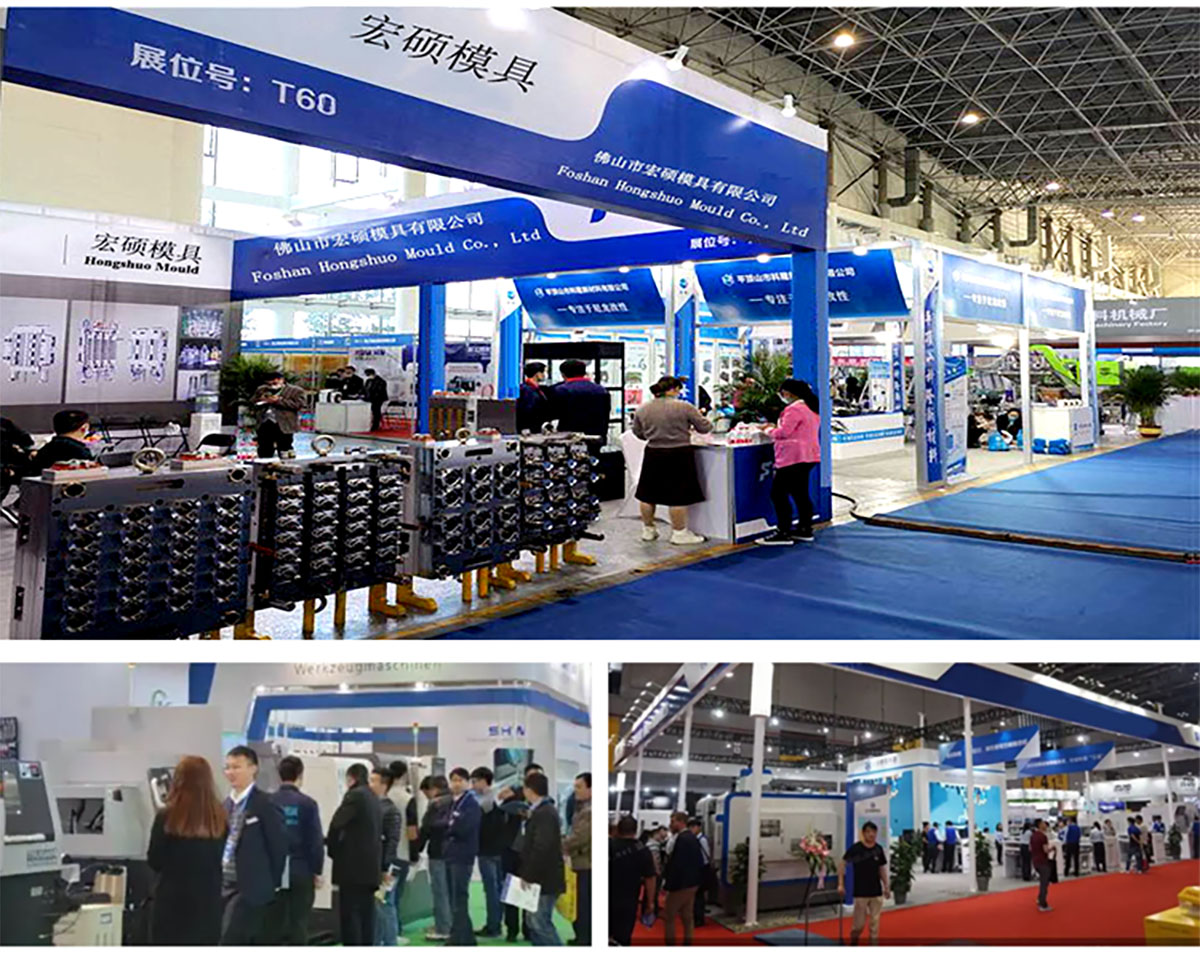

Shipment and Fair

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

One of the key factors that differentiate us from other manufacturers is our extensive experience in making molds for different types of products. From home appliances to toys, 3C electronic products, auto parts, daily necessities, etc., we have successfully manufactured molds for various categories. This diverse experience gives us valuable insight into the specific requirements and nuances of each industry, enabling us to provide tailor-made solutions to our clients.

Our dedication to precision in every mold we produce is what drives our success. We know that in injection molding, precision is of the essence, as even the slightest deviation can affect the quality and functionality of the final product. To ensure the highest level of precision, we invest in cutting-edge technology and continuously upgrade our manufacturing processes. Our team of skilled engineers and technicians work meticulously to ensure that each mold is designed and manufactured with the utmost precision, resulting in products that meet the highest industry standards.

FAQ

1. Do you sell spare parts for die casting mould?

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

2. What is your mold insert made of?

HSLD: Our mold insert is made of DAC.

3. What is your moving core made of?

HSLD: Our moving core is made of FDAC.

4. What is the tolerance of your moving cores?

HSLD: The grinding dimension tolerance of each mold core is 0.02mm and the engraving dimension tolerance is 0.02mm, so that we can ensure that the product size does not have any serious size deviation.

5. Can only samples be produced?

HSLD: Yes.

6. What is the accuracy of the products processed by the drawings?

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm

7. Can injection products be surface treated? What are the surface treatments?

HSLD: It is ok. Surface treatment: spray paint, silk screen, electroplating, etc.”Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for Factory Selling Quick Prototype Custom Plastic Injection Moulding Parts Polyurethane Molding Mould Mold Tooling Accessories Maker in China with ISO Certification, We’ve been glad that we have been steadily escalating using the energetic and long lasting assist of our pleased shoppers!

Factory Selling China Plastic Mold and Plastic Molding Service, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of “Standing in Domestic Markets, Walking into International Markets”. We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

-

Factory Directly supply Customized Plastic Wate...

-

Hot New Products Professional Plastic Injection...

-

OEM Manufacturer Custom Made Plastic Injection ...

-

2019 China New Design Ice Cube Mold Ice Trays, ...

-

Professional Design Plastic Mould Injection Mol...

-

Low price for Custom Cheap Price High Quality P...